Mould Design & Reverse Engineering

Mould design is a critical stage in the manufacturing process, where precision and innovation meet to ensure high-quality molded parts. Using advanced CAD software and simulation tools, engineers create 3D models that optimize material flow, cooling, and ejection mechanisms. Every detail—from draft angles to parting lines—is meticulously planned to achieve efficiency and product integrity.

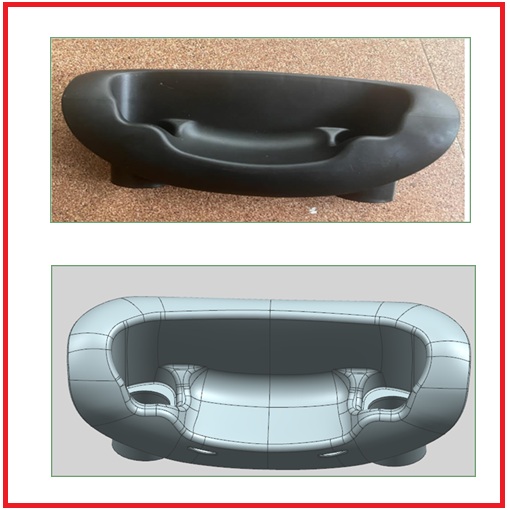

Reverse engineering allows manufacturers to analyze and replicate existing products or molds. It involves 3D scanning, digital modeling, and detailed analysis of geometry and performance. This process is especially useful for legacy components, competitive benchmarking, or design improvements. Reverse engineering supports innovation, cost-saving, and faster product development cycles.

Key Highlights

- 3D CAD modeling of complex mould components

- Flow, cooling, and structural simulation for optimized performance

- Reverse engineering through 3D scanning and digital reconstruction

- Support for legacy parts and mold rework through accurate modeling

- Reduced lead times and improved mold accuracy